There are not many topics more pertinent to onsite safety than personal protective equipment, commonly known as PPE in the construction industry. This is the clothing and gear that’s specifically intended to keep the wearer from harm. It can include anything from safety goggles for shielding the eyes to harnesses and fall arrest systems that prevent workers falling from a height. Even a simple hi-vis garment can be considered a form of PPE, protecting the wearer by making them easily spotted.

Therefore, a toolbox talk or two on personal protective equipment is highly recommended. Just about every worker on a site will be using this equipment at some point—even the suits don hard hats from time to time! We will break down the points to hit for an effective PPE toolbox talk.

Toolbox talks should always be relevant to the workers listening, so you may wish to focus on the most-used personal protective equipment or PPE items in your talk. Alternatively, you may create smaller discussion groups based on which workers use which items if there are clear distinctions.

First Things First...

The first step in using personal protective equipment is to carry out a jobsite safety/hazard analysis which, among other things, will tell you who needs to wear and use which items.

A toolbox talk should cover the findings from such an analysis. Transparency is important, and your workers should know exactly why they need to wear the clothes and use the equipment they do. It’s a good idea to use a theoretical incident as an example, or a historical one, to demonstrate and drive home what could happen should PPE rules and regulations be ignored.

Understanding how the necessary equipment can protect, and what it protects from, is crucial to getting all workers on board with using it correctly and at all times. So rather than diving straight into the nitty-gritty of how to use specific bits and pieces of PPE, begin with the reasons for it.

Different Personal Protective Equipment To Cover

To cover all of the different categories of equipment in one toolbox talk might be a little much, so use discretion as to how to break down your topics and who needs to hear what.

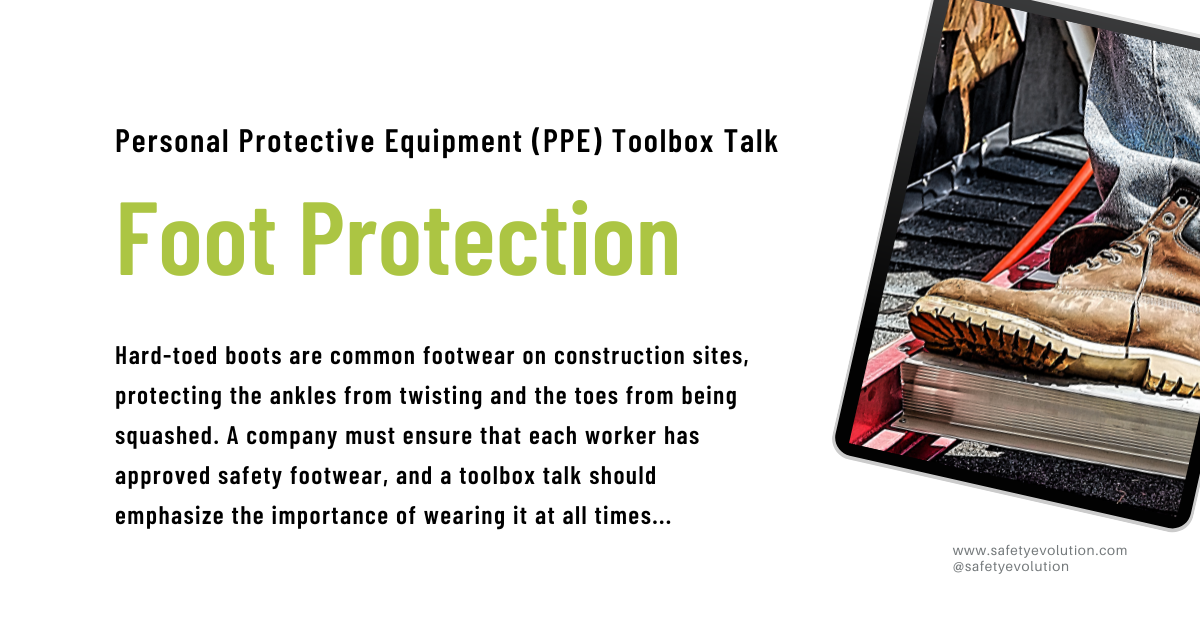

Foot Protection

Feet and ankles are an at-risk part of the body—whether that’s from heavy things being dropped on toes, or injury or sprain due to physical exertion. Bodies like CCOHS and OSHA have plenty of resources around foot protection, and regulations too. Ensure that the foot protection used on your site is in line with the local or national standards.

Hard-toed boots are common footwear on construction sites, protecting the ankles from twisting and the toes from being squashed. A company must ensure that each worker has approved safety footwear, and a toolbox talk should emphasize the importance of wearing it at all times. Foot injuries greatly affect mobility, and for manual workers that’s not good news, so offer some examples of what the consequences of inappropriate footwear could be.

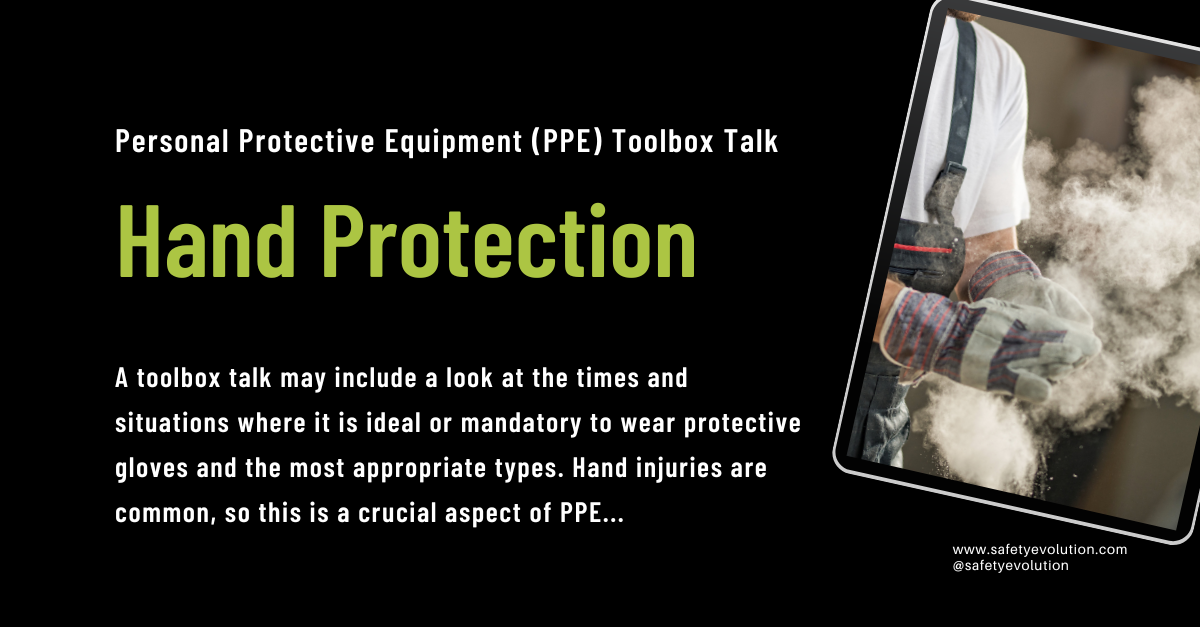

Hand Protection

Unlike foot protection, hand protection is not practical to wear at all times. A toolbox talk may include a look at the times and situations where it is ideal or mandatory to wear protective gloves and the most appropriate types. Hand injuries are common, so this is a crucial aspect of PPE.

Hand protection can be used when handling sharp things—in this case, tough leather gloves. It is also used to avoid burns by chemicals or heat, to create a barrier against bodily fluids and harmful germs (silicone gloves), or for protection against friction abrasions when handling ropes and the like. Different materials have different levels of cut resistance, and this can be pertinent information for your workers.

It’s also important to talk about good glove-wearing protocol. Gloves should fit well, as those which are too small impede movement and those which are too big can get in the way. They should be used with caution near moving equipment.

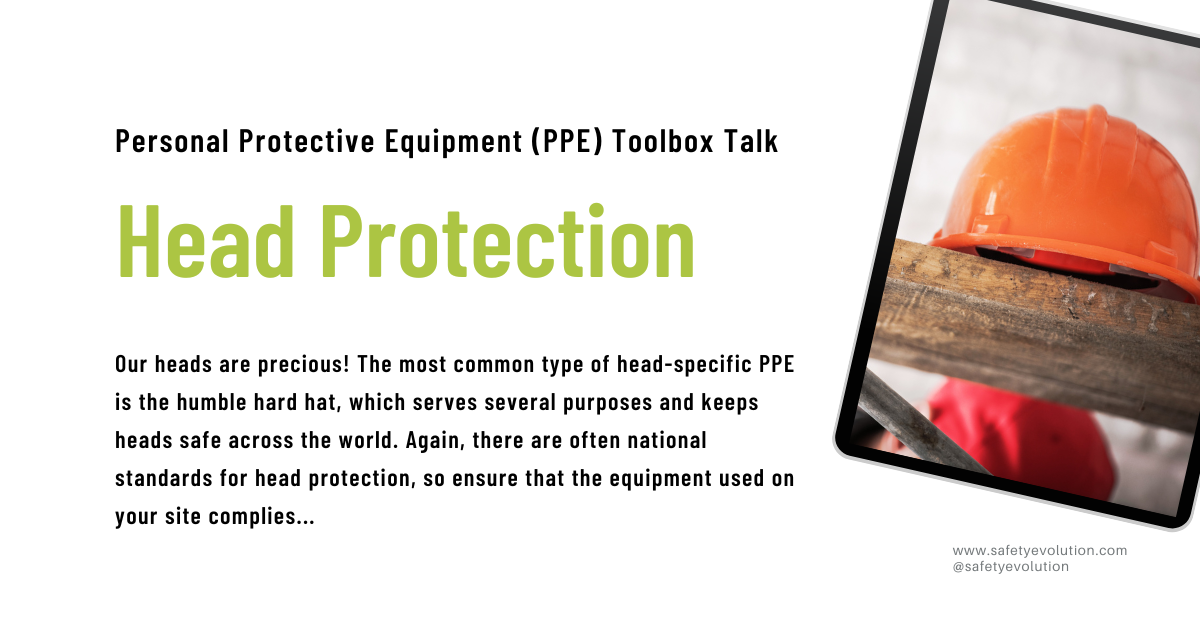

Head Protection

Our heads are precious! The most common type of head-specific PPE is the humble hard hat, which serves several purposes and keeps heads safe across the world. Again, there are often national standards for head protection, so ensure that the equipment used on your site complies.

According to several regulating bodies, hard hats are divided into two types and three electrical classes.

- Type I hard hats mitigate blows directly on top of the head.

- Type II hats mitigate blows from either the top or the sides.

- Class E (Electrical) hard hats protect against up to 20,00 volts.

- Class G (General) hard hats protect against up to 2,200 volts.

- Class C (Conductive) hard hats are not protective against electricity.

Part of a toolbox talk may include educating workers on the different types of hard hats and when each type should be used.

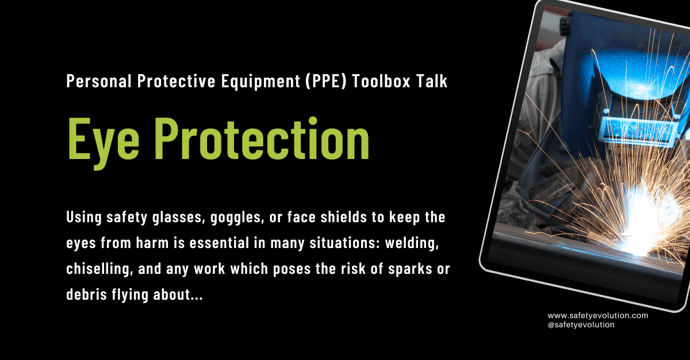

Eye Protection

Using safety glasses, goggles, or face shields to keep the eyes from harm is essential in many situations: welding, chiselling, and any work which poses the risk of sparks or debris flying about. Safety glasses are similar to sunglasses, but with a wraparound lens to protect from the sides. Safety goggles provide an even closer fit, protecting the eyes from all angles. For jobs like welding with a significant danger of sparks, hot liquids, or chemicals reaching the eyes, full-face shields are often used.

A toolbox talk might outline the different situations in which each type of eye protection PPE should be used, and could include some examples of the consequences of not doing so—like corneal flash burns.

Hearing Protection

This one might fly under the radar a little, so it’s important to point out that the very loud noises on a construction site can be harmful to the ears. Typically, ear protection consists of earplugs, earmuffs, or ear caps. Each may be used in different situations, one of the selection criteria being whether the bulk of ear muffs on the head will impede the use of other necessary equipment.

Points to cover in a toolbox talk include:

- At what levels of noise ear protection should be used. This information from OSHA is useful in determining what can cause hearing loss and how to recognize it when it becomes an issue.

- Earplugs should be changed regularly for sanitary reasons, and never shared.

- Earmuffs should be kept in good shape, with padding intact and no loose parts.

Fire-Retardant/Flame-Resistant Clothing

When there is any chance of exposure to flame, sparks, or electrical arcs, fire-retardant or flame-resistant clothing will be necessary. There are many different aspects and standards of such clothing that should be taken into consideration, including arc rating which rates how effective it is at warding off electricity. For low-risk conditions where heat is the main concern, thick cotton or wool may be acceptable. Good protective clothing will resist ignition, will not melt under high temperatures, provides a degree of thermal insulation, is strong to avoid tears which will expose skin, and reduces burn injury. It is worn as the top layer of clothing.

As with any PPE, there are regulations and requirements put out by national governing bodies that will determine what workers need to wear. Many companies choose to provide PPE that goes above and beyond those regulations, to ensure all workers are completely safe from heat or electrical burns. A toolbox talk might include the risks of not wearing the appropriate clothing and some transparency about how the company decides when it will be used.

Make Sure You’re Safety Is Covered

Having the right personal protective equipment, ensuring that everyone who needs it has access to the right items and educating all workers on when and why it is necessary—it’s a lot to think about. However, protecting everyone from risks on a construction site should be the number one concern of any construction company.

Safety software like the Safety Evolution platform can help organizations to manage their safety-related paperwork, checklists, and training schedules to put the focus where it should be: on keeping each and every person safe in the field.

Safety Evolution's Free Toolbox Talk Download Package

Finding toolbox talks for your safety meetings last minute can be a hassle.

Download this free package of weekly toolbox talks such as Hand Tool Safety, Forklift Safety, Trench Safety, Workplace Violence, Housekeeping toolbox talk, and more to make life easy!

Sign up below to receive our weekly newsletter with helpful safety content including weekly toolbox talks!