Is your audit date sitting on the calendar like a countdown clock?

If you’re a contractor running work with a lean team (no full-time safety department), audits have a way of turning into a last-minute scramble:

Whether it’s OSHA, COR/SECOR, a client/GC audit, or a prequal review… the stress is the same.

Here’s the good news: passing your audit usually isn’t about creating brand new paperwork. It’s about tightening the few parts of your system that auditors actually test.

If you want a fast, contractor-friendly way to see what would get flagged in your program before your audit, book a free Safety Assessment. We’ll pinpoint the 1–2 gaps that usually cause audit findings and give you a clear fix plan.

The 3 Strategies Checklist For Safety Audits

Every successful program starts with a plan. The plan for passing your safety audit can be broken into three focus points:

-

People

-

Paperwork

-

Process

These three areas cover what auditors actually assess:

1. People - The Starting Point for All Safety Audits

Start with your people. They make or break an audit because they:

-

complete the documents the auditor reviews

-

answer the auditor’s interview questions

-

get observed implementing your program on site

A lot of companies try to “prep for interviews.” That’s backwards.

The goal isn’t to coach answers. The goal is to run a safety program that’s communicated so consistently that your workers can answer basic questions naturally because they actually know the expectations.

What to do all year (not the week before):

-

Make safety expectations part of the weekly rhythm (not a monthly “checkbox”)

-

Train supervisors and foremen on what “good” looks like on your jobs

-

Onboard new hires the same way every time (so the weakest link isn’t the newest guy)

-

Keep toolbox talks short and tied to what’s happening on site this week

Helpful resources:

If your worry is, “My crew would freeze if someone asked them to explain our process,” book the free Safety Assessment. We’ll tell you exactly what auditors typically ask in interviews and what to tighten first.

2. Paperwork - Where Most Companies Lose Points (And Time)

Paperwork isn’t the point of safety… but it’s how you prove your system exists. Most audit failures aren’t “you had nothing.” They’re:

-

missing documents

-

inconsistent forms

-

documents completed wrong

-

no proof of reviews

-

corrective actions never closed

-

training proof scattered across texts, emails, and gloveboxes

Here’s the hard truth: Paperwork needs to be reviewed when it’s done, not weeks later when you’re trying to assemble an audit package.

Simple upgrades that make a huge difference:

-

Standardize your core forms so every crew uses the same versions

-

Set a rule: paperwork gets reviewed within 24–48 hours (not end of month)

-

Build a basic corrective action loop: assign it, track it, close it

-

Keep proof in one place so it’s not a scavenger hunt when someone asks

Helpful resources:

If you’re thinking, “We do the work, but our proof is everywhere,” book the free Safety Assessment. We’ll map what documentation you need for your next audit and show you how to organize it so it’s pullable in minutes.

3. Process - How You Stay Audit Ready Without A Last-Minute Scramble

The secret to passing audits isn’t working harder in the final two weeks. It’s having a process that runs weekly so the audit is just a snapshot of what you normally do.

Auditors are checking whether your system is working:

-

inspections happening on schedule

-

hazards identified and addressed

-

incidents investigated properly

-

corrective actions closed

-

training completed and documented

-

supervisors enforcing expectations consistently

Ask yourself:

-

Do we have owners for each key part of the program (or is it “everyone,” meaning no one)?

-

Do we set time aside weekly to keep the program running?

-

Do we catch issues early, or only when something goes wrong?

What “audit-ready” actually looks like:

-

A weekly 30–60 minute safety admin block that never gets skipped

-

A simple checklist so nothing falls through cracks

-

A tracking system for corrective actions and follow-ups

-

A routine for reviewing inspections, FLHAs, and training completion

-

A quick internal check 30–60 days before the audit (not 7 days)

Helpful resources:

If you want to walk into your next audit calm, book the free Safety Assessment. We’ll give you a simple 90-day “audit-ready” plan based on what’s missing right now, not a generic binder rewrite.

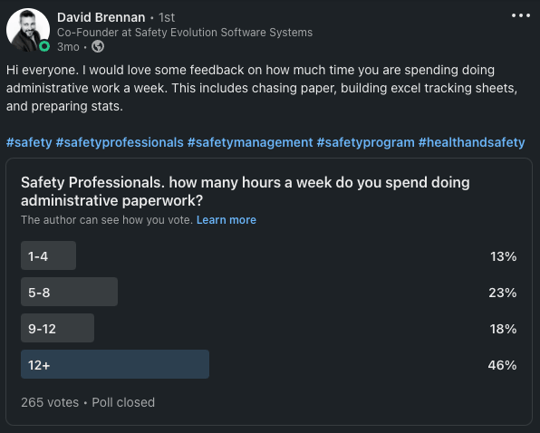

FYI from Safety Evolution - We polled 265 safety professionals on LinkedIn and 46% spent over 12 hours a week completing the required safety paperwork and administrative duties required to keep their safety programs running properly.

The Goal - Get Prepped, Stay Prepped For Your Next Safety Audit!

A safety audit isn’t just about documents. A good auditor will look at:

You can’t fake that in two weeks.

But you can absolutely tighten it with the right focus:

People. Paperwork. Process.

If you want us to pinpoint the 1–2 gaps most likely to cause audit findings (and show you the fastest way to fix them), book your free Safety Assessment here.

Sign up to receive our weekly newsletter with helpful safety content below!